Europe doesn’t have a technology problem. It has a hands problem.

The skilled trades are collapsing. Companies can buy tools, machines, and robots. What they can’t buy are the people who know how to use them. That’s why Strauss moving into XR matters more than any AI announcement this week. They’re not building a gadget. They’re building the future workforce.

Here’s what they got right.

The AI Insights Every Decision Maker Needs

You control budgets, manage pipelines, and make decisions, but you still have trouble keeping up with everything going on in AI. If that sounds like you, don’t worry, you’re not alone – and The Deep View is here to help.

This free, 5-minute-long daily newsletter covers everything you need to know about AI. The biggest developments, the most pressing issues, and how companies from Google and Meta to the hottest startups are using it to reshape their businesses… it’s all broken down for you each and every morning into easy-to-digest snippets.

If you want to up your AI knowledge and stay on the forefront of the industry, you can subscribe to The Deep View right here (it’s free!).

The Crisis Everyone Feels but No One Solves

Europe’s labor shortage is no longer an economic issue.

It is a structural fault line that runs through every industry that depends on real craftsmanship. The numbers are clear. Experts are retiring faster than new workers enter the trades. Apprenticeships sit empty. Projects slow down or fail because companies simply cannot find the people to do the work. Governments respond with the same answer every time.

Import more skilled labor from abroad and hope the system absorbs them but in reality this creates new problems.

Language barriers. Integration challenges. Cultural mismatches. And above all, an unstable pipeline of workers that cannot keep up with the demand. The result is predictable. Companies face rising costs. Deadlines slip. Entire sectors become vulnerable.

This is the problem Strauss decided not to ignore.

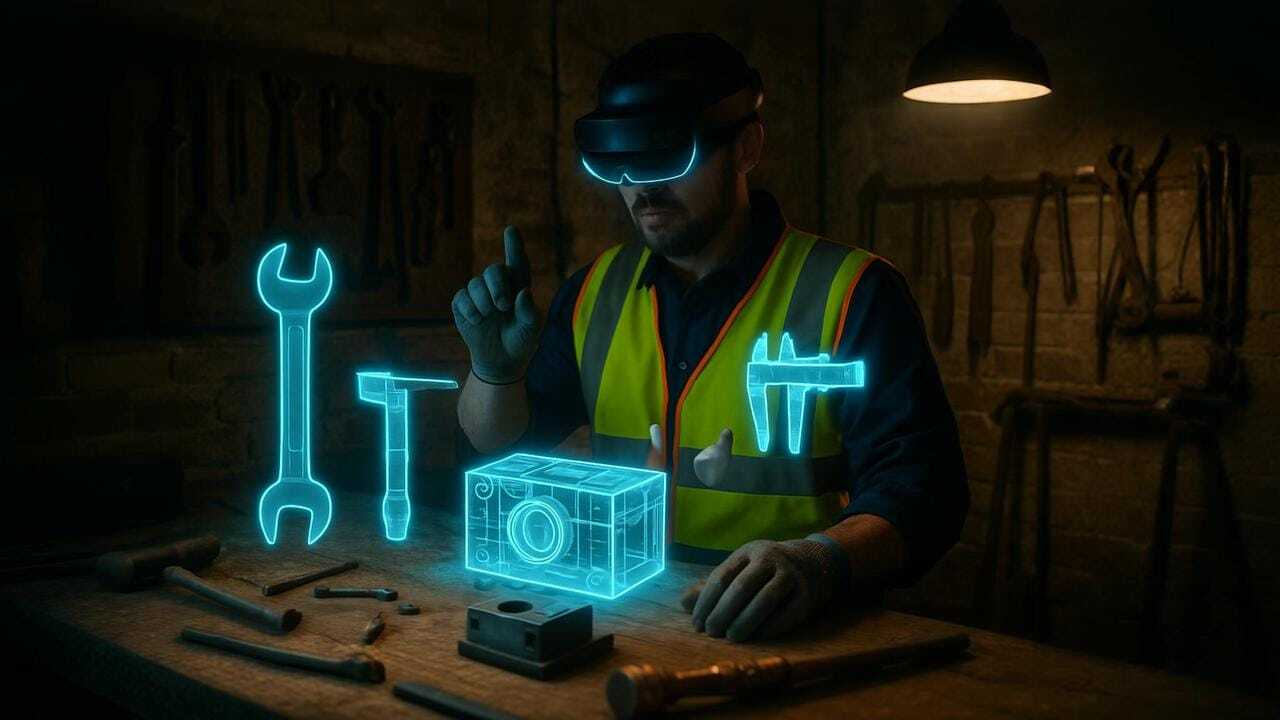

VR Tool of the Week: Toolbox XR

The most realistic XR training environment Europe has built so far.

Specs and Characteristics

Built by Engelbert Strauss in partnership with Meta

Designed for carpenters, electricians, roofers, and technical trades

Full mixed reality environment mapped to real workbench movements

Digital twins of tools with precise interaction and step-by-step workflows

Runs on Meta’s latest spatial computing hardware

Focused on repeatable training, confidence building, and measurable skill progression

“Made in Germany” engineering quality applied to immersive training

Key Benefits:

Accelerates learning because the environment feels natural

Reduces training risk and material waste

Standardizes skill across teams and locations

Helps companies attract younger workers

Scales easily without needing extra instructors

Gives workers real repetition time without interrupting daily operations

Toolbox XR is a practical step forward for the skilled trades.

It takes real tasks, real movements, and real workflows and brings them into an immersive environment workers actually understand.

It is one of the first XR systems in Europe that treats craftsmanship with respect and gives companies a scalable way to rebuild their workforce.

Who Strauss Is and Why Their Move Matters

Engelbert Strauss is not a tech company.

They are one of Europe’s largest workwear and equipment brands with a deep relationship to craftsmen across the continent. Their customers build houses. Wire buildings. Repair infrastructure. Strauss sits at the heart of that ecosystem and understands the pressure better than most. So when they step into XR, it is not a trend play.

It is a strategic intervention.

They partnered with Meta and leading XR developers to create Toolbox XR, a training environment designed to replicate the real workbench. Not a game. Not a simulation built for showrooms. A true digital twin of the tasks workers perform every day. This is where the story shifts.

Strauss went from outfitting workers to actually training the next generation of them.

HUGE XR NEWS (from last week)

Meta releases new enterprise-grade hand-tracking update for precision tasks The latest update improves micro-movements and reduces latency, making XR training for trades and industrial workflows significantly more accurate. (learn more)

Siemens expanded its digital twin ecosystem with XR scenarios that guide technicians through real machinery repairs. It is the closest step yet toward fully integrated factory-to-XR training pipelines. (learn more)

Boeing reported that XR-assisted training reduced certain assembly tasks by up to 50 percent and cut error rates dramatically. Their new pilot program will scale XR to additional teams in 2026. (learn more)

South Korea launches national XR workforce initiative The government announced a major investment package to train over ten thousand workers per year using immersive learning. Their goal is to counteract the shrinking skilled labor pool and build a future-ready workforce. (learn more)

Trimble introduced a mixed reality system that teaches surveying, measurement, and onsite construction workflows with real-world accuracy. It is designed for companies that need scalable training without disrupting active job sites. (learn more)

Why This Approach Works and What It Unlocks

Toolbox XR solves two problems at once.

It supports companies that need skilled labor now and helps attract the next generation that views the trades as outdated. Here are the most important benefits.

It makes training faster.

Workers build confidence quickly because the environment feels natural.

It removes risk.

Beginners can repeat tasks until they master them without breaking tools or materials.

It helps with recruitment.

Young people respond to interactive and visual learning. XR gives them a modern entry point.

It standardizes skill.

Every learner follows the same steps which increases safety and reduces quality variation.

It scales.

You can train ten workers or one hundred without needing ten instructors or ten physical workstations.

This is the bridge the industry has been missing.

Did you know?

Skill shortages cost the construction industry an estimated $49 billion every year due to delays, rework, and extended training time.

This is one of the strongest economic arguments for immersive training.

Source: McKinsey – Addressing the Future of Workforce Development in Construction (learn more)

What This Signals for Europe’s Future

Strauss is not launching a gadget. They are showing how industries can secure their own future. Europe cannot rely on schools, migration, or policy changes to fix the trades shortage. It needs practical systems that build skill fast and at scale.

XR is becoming that system.

It protects knowledge, accelerates training, and gives companies a real path forward. Strauss set the example. Now it is on companies to act.

If you want to explore what an XR training system could look like for your team, reach out to us below. We will walk you through a personalized plan based on your workforce, your tools, and your real environment.

That’s a wrap!!

Talk soon!

Bruno Filkin

Founder, Mastermind VR

VR Strategy Consultation

Ready to explore VR training for your team?

Take the Next Step

Let us review your project and discuss possible development and production details.

👇🏼